New Two Storey Steel-Framed Building

New Two Storey Steel-Framed Building

Housing four separate data centres along with external Generators, switchgear and utility substations.

Housing four separate data centres along with external Generators, switchgear and utility substations.

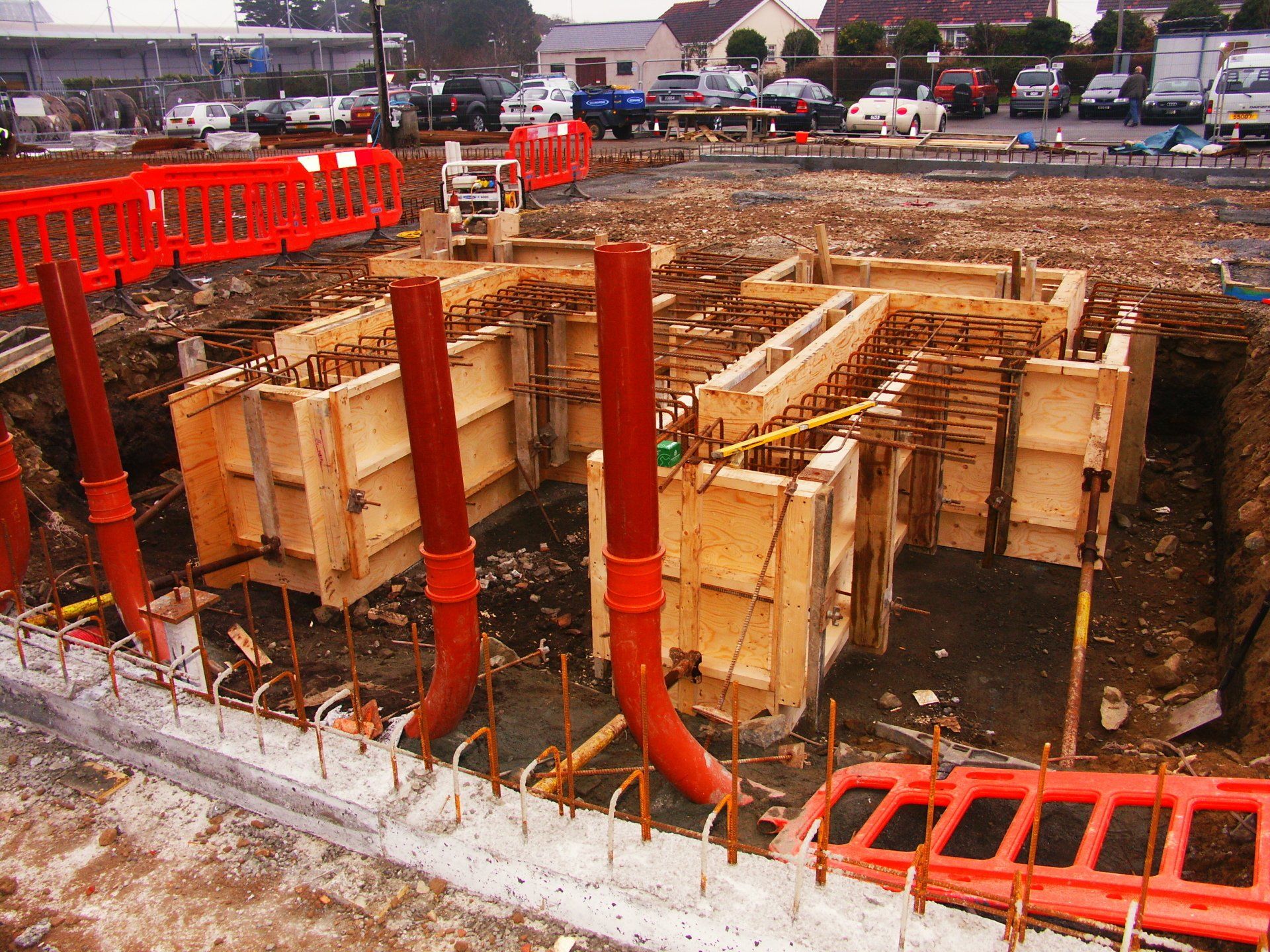

Construction of a brand new two-storey, steel framed building housing four separate data centres - two on each floor. Each data centre is identical in size room with a maximum capacity of 75 racks @ 5KW each. The new building would be clad using Kingspan panelling and have a load bearing front landing platform and an internal lift rated at 2000Kg. Two external concrete service slabs would house four diesel generators (with associated fuels tanks), automatic mains failure switches and new mains transformers provided by the local utility company. My remit on this exciting project was to plan and co-ordinate all pre-project activities and then undertake the dual role of project and site manager.

Challenge

Challenge

A major challenge for this project was the fact that the whole campus sat on top of an old quarry. As such, an extensive groundworks programme would be required which would involve extensive piling. The area surrounding the campus was a mix of residential and business properties. This could have proven problematic as piling activities inhererntly create substantial noise and vibration. Through careful management and close communication with residents (via letter drops), the groundworks passed off without incident or complaints.

The project took place on a small island which meant the numerous deliveries deemed as 'abnormal' had to be performed out-of-hours with an appointed escort. Once again, this required careful management and co-ordination with suppliers, the shipping agents and the local authority departments. The majority of the suppliers and subcontractors were based off island which in itself, posed unique challenges for a project of this nature.

Outcome

The new building was completed and officially opened in the summer of 2009. Two of the four rooms were fully built out (Phase 1) with all M&E infrastructure. A gaming client took up residence in the two rooms which were converted into private suites.

A second project took place in 2010 to install the full M&E plant in rooms 3 and 4 (Phase 2). In conjunction with this, the associated generators, fuel tanks, mains failure switches and sub-stations were also installed.